Products and Services

We have continued to pursue the potential for plastic containers using our unique injection stretch-blow molding technology.

Products and Services

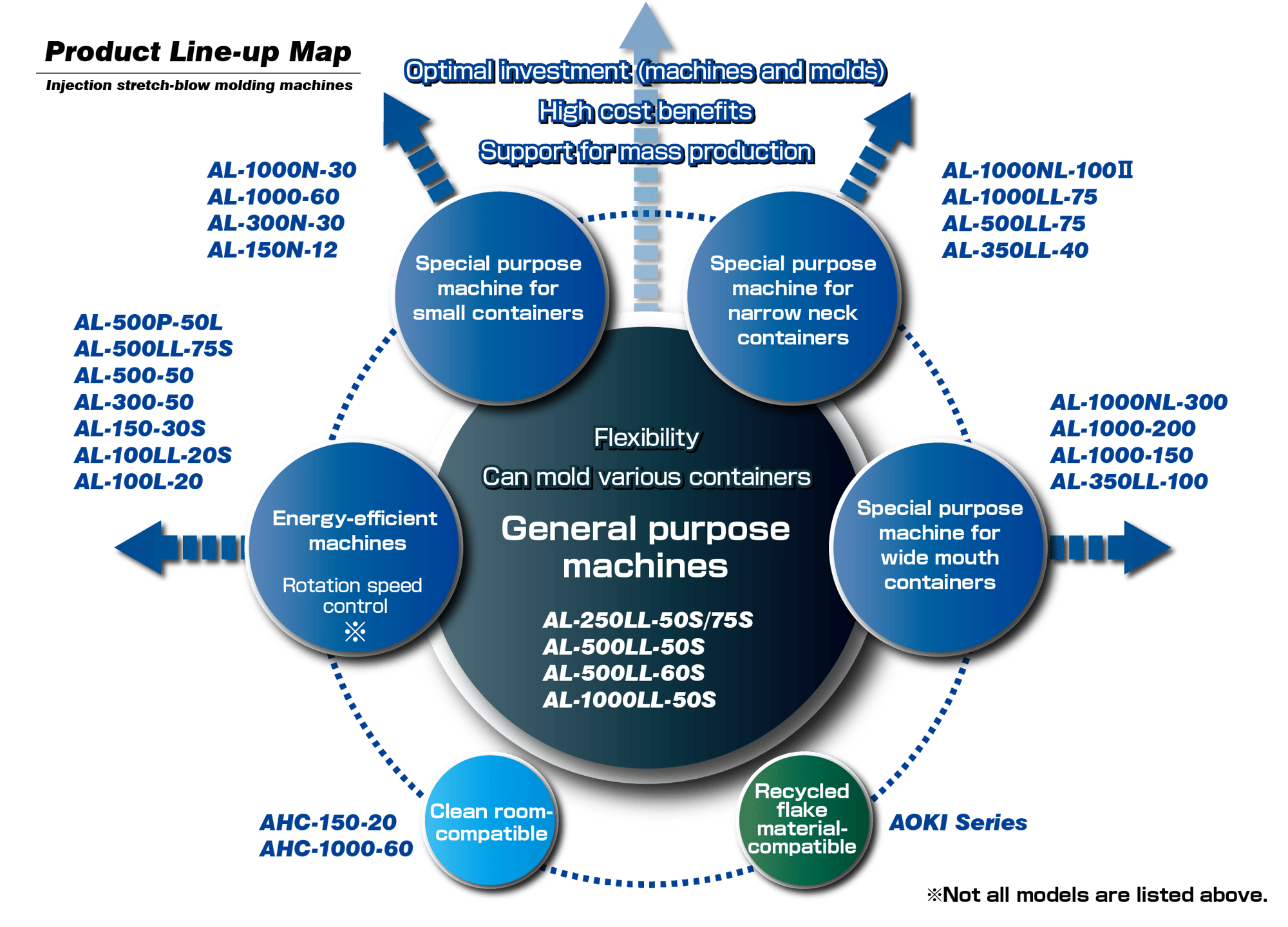

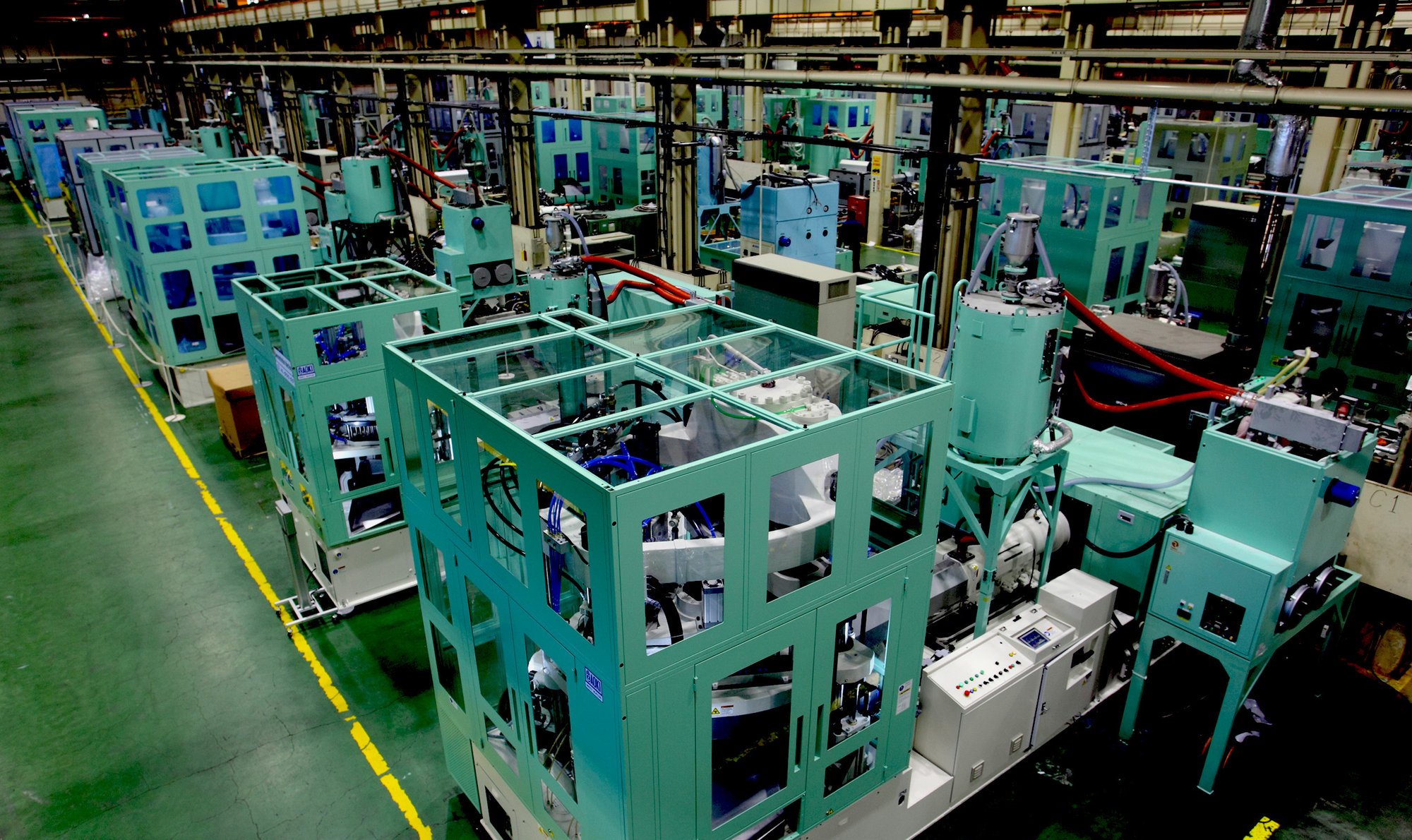

Injection stretch-blow molding machines

Our molding machines offer tremendous benefits tailored to the containers you produce and your business goals.

Capable of molding a wide variety of containers from small containers to wide mouth containers, our general purpose machines deliver multifaceted value and flexibility to accommodate changes in your container business. The biggest feature of our AL series is, however, special purpose machines designed to deliver maximum business benefits. Whatever your needs, we can support you by optimizing container design, reducing material use, shortening molding cycles, supporting mass production, and more.

Reduced electricity consumption with rotation speed control

Electricity bills are rising throughout the world as electricity prices continue to soar. At Aoki, we have long been preparing for such an eventuality, so our time has come.

We recommend our rotation speed control-equipped machines for the way they can help reduce electricity consumption and production costs.

| Machine model | AL-300-50 | SBⅢ-250LL-50S | AL-500LL-50S |

| Pressure retention circuit +rotation speed control |

Older model | Pressure retention circuit | |

| Cycle | 15.8sec | 15.8sec | 12.8sec |

| Power consumption | 15.2kW | 23.5kW | 28.6kW |

| Power consumption decrease | 35.30% | 46.90% |

The decrease is close to 40% for most models.

Please contact us regarding production costs and other details.

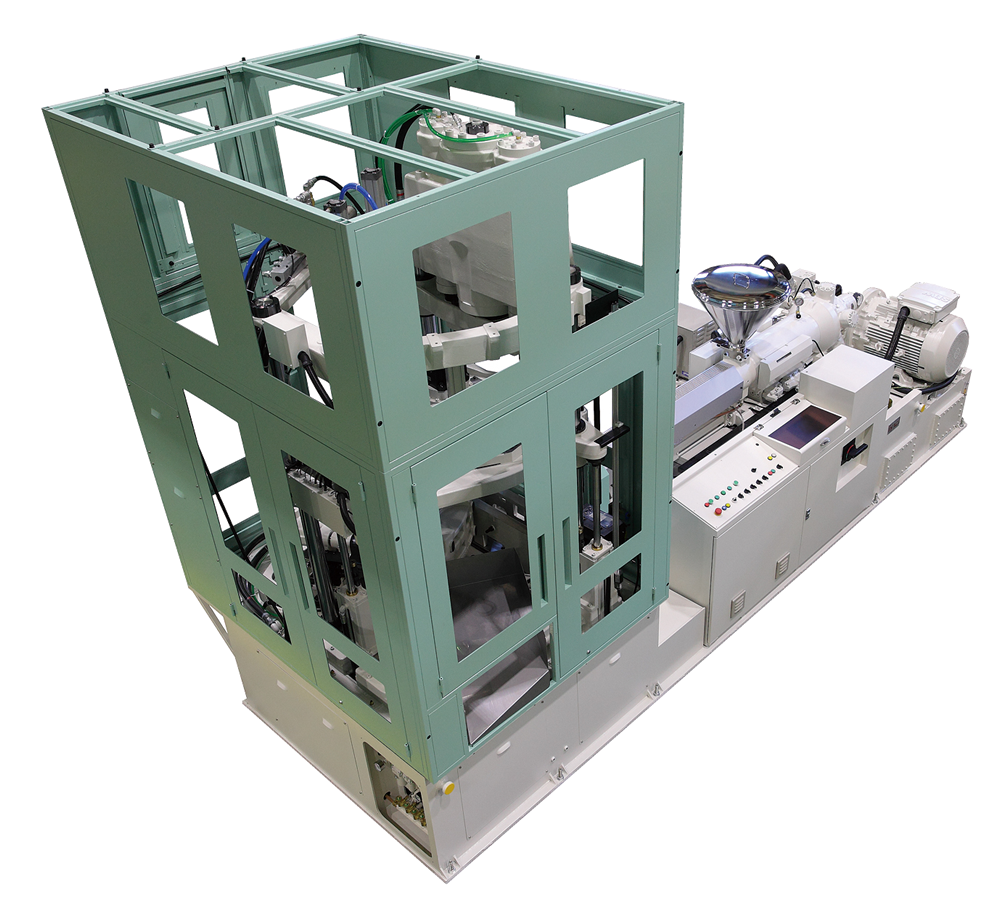

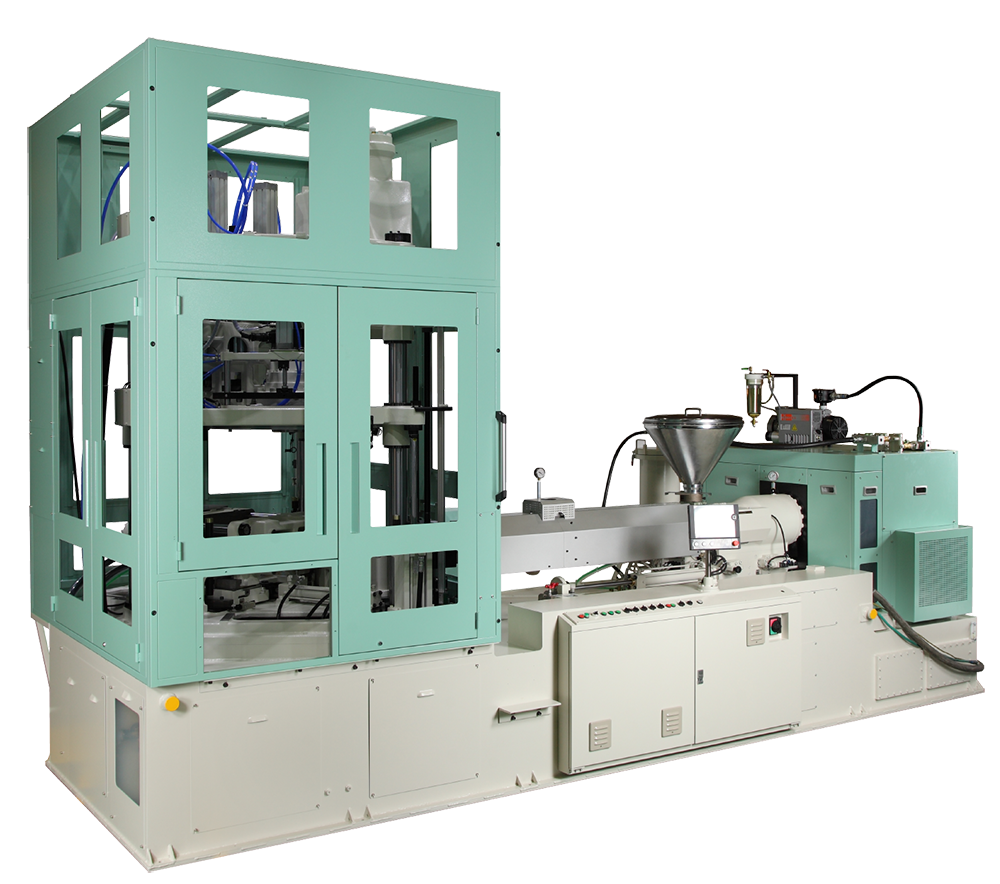

Injection stretch-blow moulding machines

AL Series

We have long sought to improve molding machine control technologies, container and mold design technologies, and molding technologies with the aim of enabling the production of high added value containers using minimum time and energy.

The advances resulting form our efforts can significantly shorten molding cycles for containers with the same product specifications.

If you are looking to further cut your production costs and expand your container production business, do not hesitate to consult us.

Products and Services

Special purpose machines for optimizing container business

At Aoki, we utilize our extensive experience in the development of injection stretch blow molding machines to provide molding systems that meet the needs of our customers' container businesses. We offer special purpose molding machines tailored to container purpose (contents and usage environment), production volume and other conditions.

We can also address special molding demands such as molding with special materials, clean room molding, and factory inline molding. Whatever issues you face, let us know about them. We will do our utmost to help you build the ideal molding environment.

Products and Services

Greater flexibility

The AL Series enables outstanding high cycle molding with a wide variety of molding materials for all sorts of applications. Even for low specific gravity PP/HDPE or heavy, thick-walled containers, injection capacity does not constrain cavity number.

We are now able to mold high-quality containers by applying ISBM advantages to molding areas such as PE (polyethylene), which previously required extrusion blow molding.

You can also expect to be able to significantly increase production volume by eliminating excessive and unnecessary specifications. AL machines can manufacture all kinds of containers from low to high value-added containers.

Products and Services

High-speed mold release technology

High-speed mold release is a molding method that can dramatically boost production volume by minimizing preform injection and cooling time. We developed it as a new alternative to molding in which cycle time is determined by biaxial orientation molding theory and preform thickness.

By making the most of this molding method, you will dramatically increase production volume of the same container compared with your current method.

Products and Services

Equipped with high plasticization unit

There are many other advantages in addition to high cycle molding to combining high plasticization units with conventional mold clamping mechanisms. One of those advantages is greater plasticizing capacity at low temperatures.

This enables preforms to be molded at lower temperatures, thereby shortening injection/cooling time. As a result, molding cycle time is also not constrained by metering time. Furthermore, improved melting and kneading capabilities result in better molten resin condition at lower speed rotation, helping to enhance the moldability of a wide variety of molding materials.

Products and Services

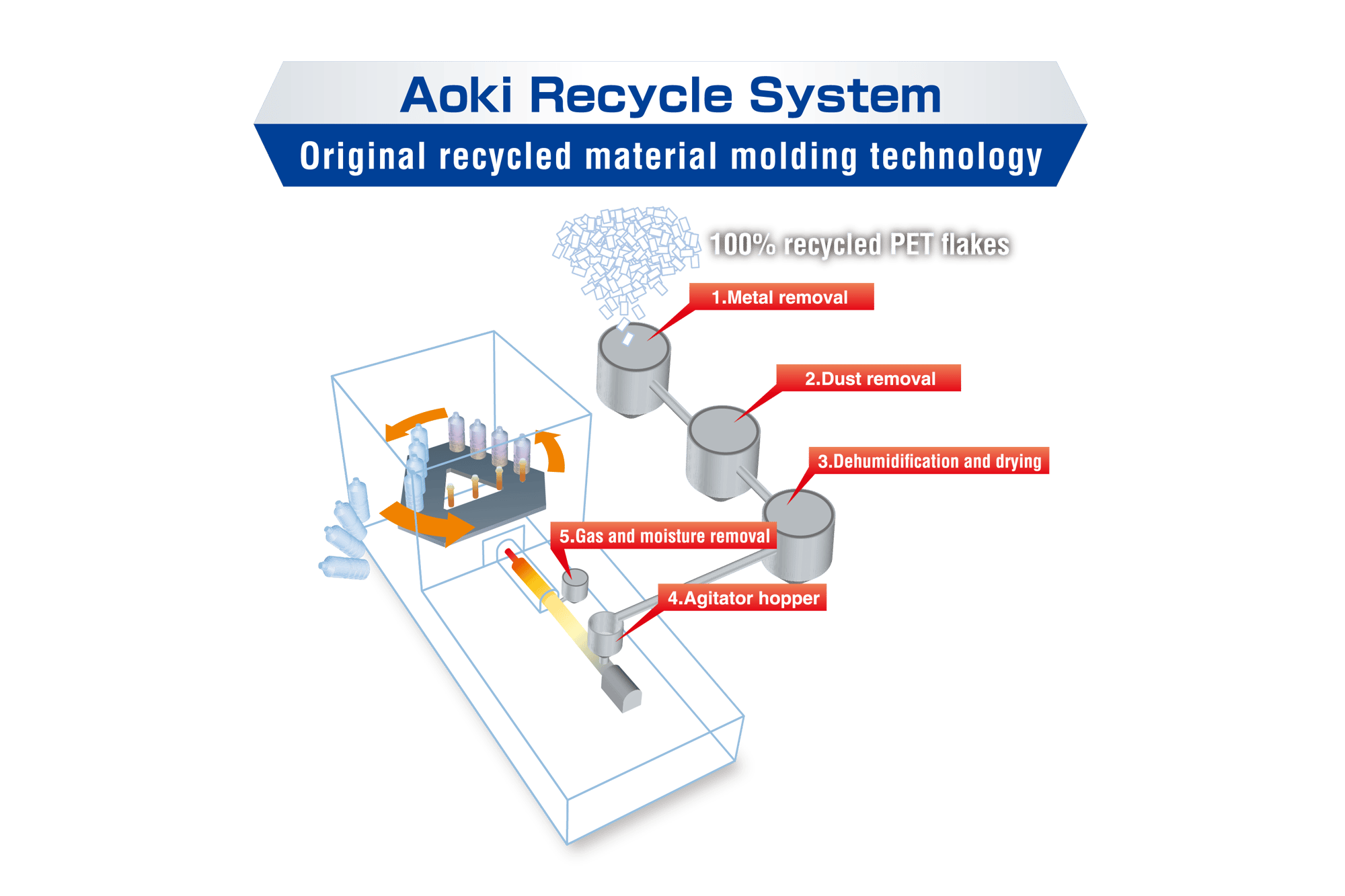

AOKI Series: Injection stretch blow molding machines that support 100% PET flake molding

AOKI Series machines are injection stretch-blow molding machines that enable containers to be molded directly from flake material made from ground, washed PET bottles.

The mainstream approach to recycling PET used to require pellet material, but with the AOKI Series machines, costs associated with re-pelletizing or re-crystallizing the recyclate are now a thing of the past.

Molding recycled flakes directly into containers

AOKI Series machines use a unique barrel venting system that removes moisture content and impurities from the resin, making stable production of high quality products possible.

Total support for container production

Total support from the planning and idea stage to production and maintenance

Preventive maintenance activities and support

Maintenance support program for preventing machine breakdowns and other problems

Products and Services