Technologies

Aoki’s unique molding method

Aoki technologies

The advantages of molding containers

from material at highest speed worldwide

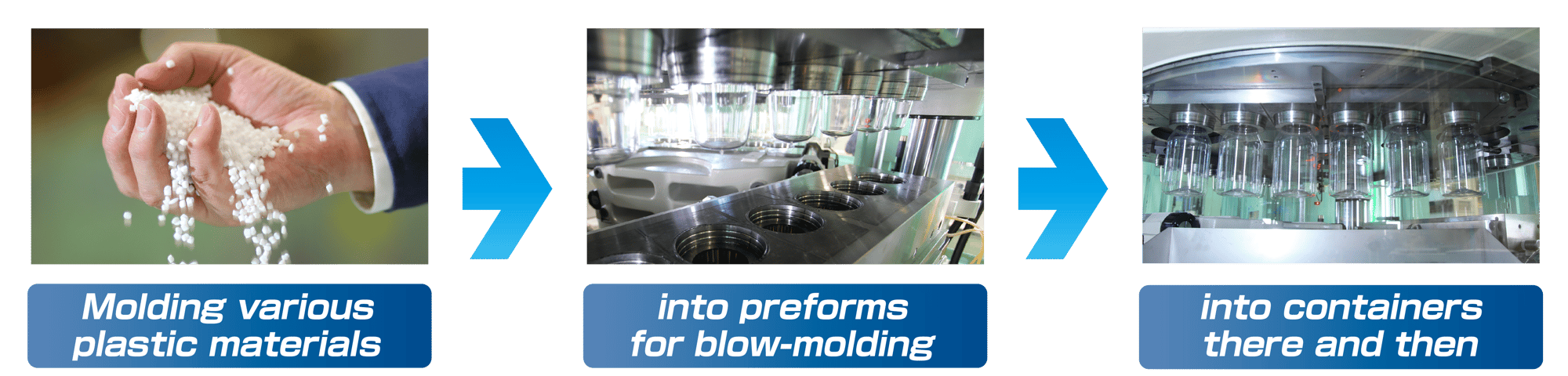

This material will be melted and shaped into preforms that are then immediately blow-molded in what is the world’s fastest material-to-container manufacturing process.

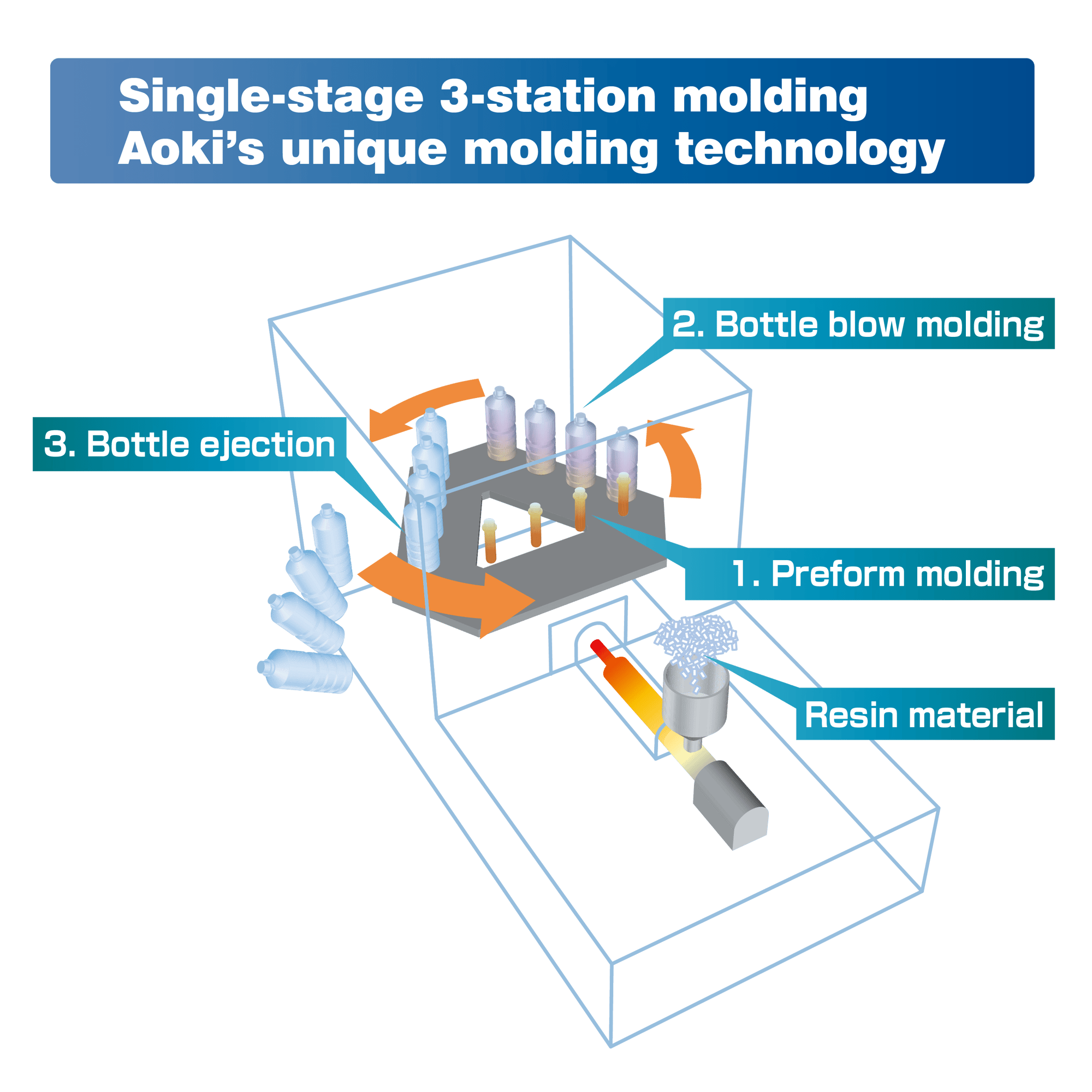

Using our proprietary molding technologies, our molding machines melt resin material, mold preforms, and then immediately stretch-blow them to produce containers. The speed with which the raw material is converted to finished products in a single rotation through the molding machine’s three stations is unmatched worldwide. The longer it takes to complete a product, the more energy the process requires. By simplifying the molding process to the limits, we have achieved unparalleled speeds in converting raw material into containers.

Aoki technologies

Simple mechanism

for maximum speed

Our proprietary technology enables single-stage molding of molten material at 3 stations — 1. Preform molding, 2. Bottle stretch-blow molding, and 3. Bottle ejection.

Our proprietary Direct Heatcon molding method uses residual heat in the preforms to enable blow-molding that wastes no energy and molds finished products at maximum speed.

While new machines and molding materials are important to any consideration of how to address environmental issues, the ability to blow-mold preforms as soon as they are molded makes our machines the industry's ultimate eco-friendly molding machines.

Aoki technologies

Evolution of proprietary VE method

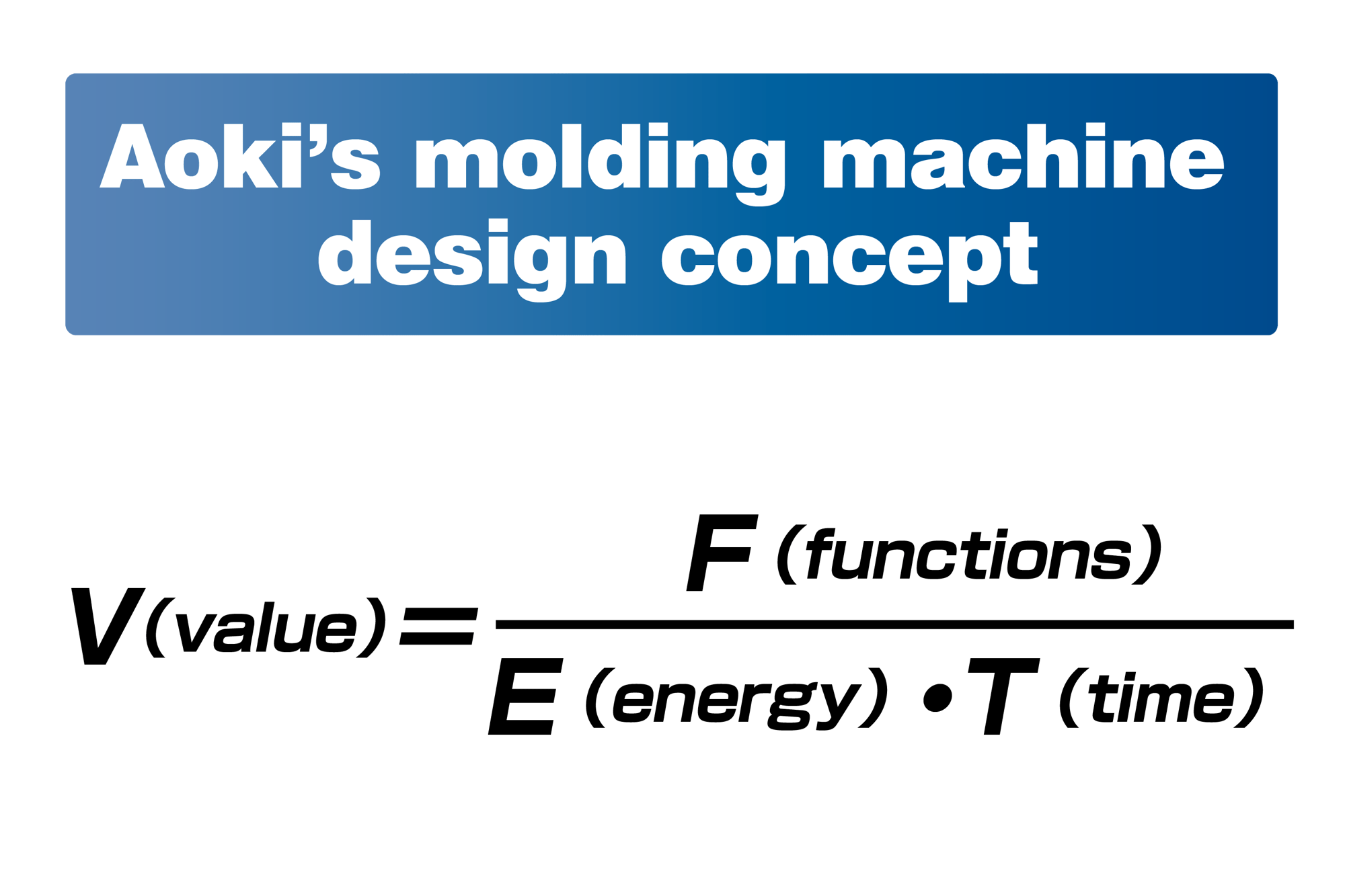

Aoki’s molding machine design concept focuses on reducing production energy and creating added value by leveraging the Value Engineering (VE) method, which uses energy and time as the denominators for generally defined costs in the equation to determine value.

Blow-molding preforms immediately after they have been molded embodies Aoki’s design concept of minimizing [energy × time], the denominator in its Value Engineering (VE) equation. Technologies such as high speed mold release and Direct Heatcon perform the function of numerators in this equation. Our proprietary technologies can add tremendous value to your container business.

Aoki technologies

Compatible with all types of containers and materials

It is because our molding machines are versatile enough to mold all types of container according to purpose, shape, and function that they have been used to mold over 10,000 types of container of different size and shape.

Another advantage of our molding machines is their ability to mold containers directly from various types of molding materials. Our machines offer the kind of versatility that enables the best molding methods to be combined according to the differing characteristics of various materials.

Technologies

Key technology: Direct Heatcon

Enabling single-stage 3-station molding, the ultimate simple mechanism, with Aoki’s unique molding method

Aoki’s ever-evolving technology

Learn more about our development of new molding technologies, machine models, and more.

Technologies

Case studies

Inquiries about molding machines and container development

Please feel free to contact us if you are considering deploying molding machines or producing containers yourself.